Our sake brewery

- Exclusive shop

- Restaurant

- Gallery

- Camping

- Farm Orchard

- Multi-purpose area

- Facilities guide

- Visitor Center

Facilities guide

Sake brewery tour

A kurabito (sake brewer) will guide visitors through the distinguished brewing process and our historic buildings.

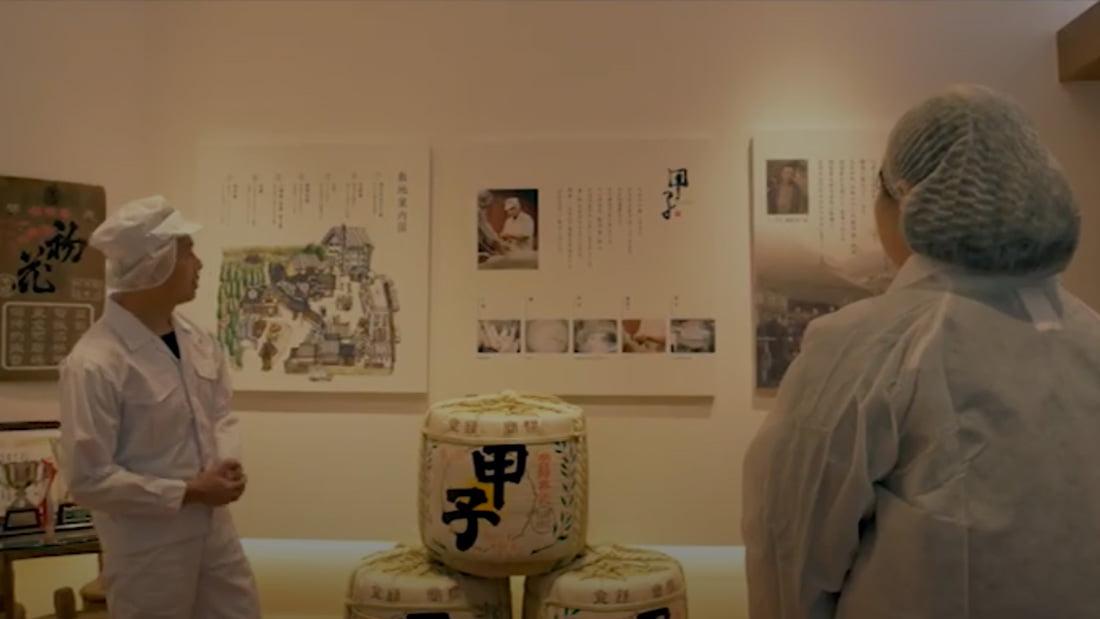

First floor entrance hall

Upon entering our brewhouse, the Hokuso Kura, visitors will be presented with lab coats to prepare for the tour. At the entrance hall are panels that explain the history of the brewery.

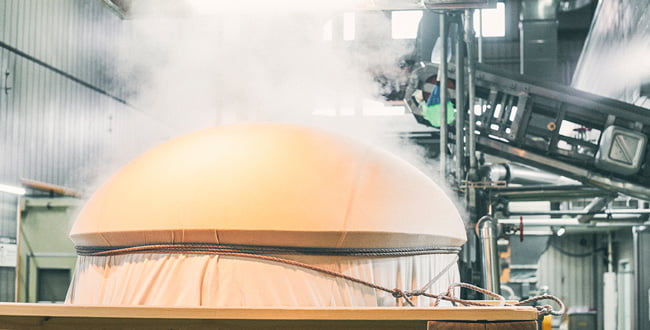

Continuous rice steamer

Saka-mai (sake rice) that has been soaked in water is carried on a conveyor belt to undergo the processes from steaming to cooling. The machine automatically adjusts the steaming time as well as the temperature and amount of steam being fed to the machine to finish the rice to a perfect state.

Koshiki

Koshiki is a large vat used to steam rice. White rice that has been washed and soaked is placed on a slatted board, and the rice is cooked by the steam generated by the boiling water from below. The koshiki is equipped with a function to produce dry steam to ensure that the rice is steamed to achieve a friable texture for easy handling.

Shubo-shitsu (Yeast starter room)

This is where the shubo (yeast starter) is created, and the process involves propagating batches of sake yeast to increase their numbers. The room is kept clean at all times as this is necessary to cultivate a pure culture of sake yeast.

Shikomi tank (Mashing tank)

At Iinuma Honke, a large, computerized tank is utilized to automate the stirring process of the moromi (fermentation mash). This enables us to reap the full benefits of mechanization while practicing the traditional artistry of sake brewing. By fusing machines with craftsmanship, we now have the capability to provide a stable supply of products to our customers while consistently maintaining high quality.

KOS (Automatic koji-producing machine)

KOS is a large-scale koji-producing machine. The multi-tiered, automatic koji maker can produce large amounts of high-quality koji at a time when utilized to its full potential by those with the expertise and skills acquired in small, old-fashioned koji rooms.

*Koji is the fungus, Aspergillus oryzae, essential to the production of Japanese sake.

Shinseki-ba (Steeping area)

Here, sake rice delivered from the rice polishing center is steeped in water. Soaking time differs depending on the variety of rice and the rice polishing ratio, among other factors.

Koji room

The koji room, where koji is produced, is constructed of cedar in the traditional style with insulated walls, floor, and ceiling. It is equipped with ventilation skylights to control the temperature and humidity and to eliminate carbon dioxide.

Funaba (Pressing room)

This room is equipped with a moromi (fermentation mash) press called fune. Currently, we use an automatic machine press that minimizes the oxidation of the sake while allowing large amounts of moromi to be pressed.

Showa Kura (Main Brewhouse) storage tank

Before the current main brewhouse was built, the wooden buildings of the New Brewhouse, Main Brewhouse, and Showa Kura all stood in the same location. However, due to aging and the necessity to introduce the latest equipment, a new four-story Hon Kura (Main Brewhouse) was built in 1966 using reinforced concrete, which was very rare at the time. Contained within this single architecture were nearly all of the facilities and rooms deemed essential to a sake brewery, with the exception of the rice steaming facility. These included the shikomi (mashing) house, filtering area, koji room, a large room serving as the sleeping quarters for the brewers, a drawing room, and a tatami hall to entertain guests. Today, it is used as a storage warehouse and filtering facility.

Seimai-jo (Rice polishing center)

Our company is one of the few breweries in the prefecture that operates a rice polishing facility. A tedious and time-consuming method of “flat milling (henpei seimai)”, as opposed to regular milling, polishes the rice to minimize its protein content, which is the source of certain off-flavors. By using flat-milled rice, we can brew a more pristine quality of sake in contrast to those made with regular polished rice.

Kinoene Kura

Kinoene Kura served as the shikomi (mashing) facility when the Kinoene Plant No. 2 was constructed in 1914 in present-day Goi, Ichihara City to expand the business. Plant No. 2 didn’t operate for too long as it was closed around 1949. After the closure, the building was relocated to the current site in its original state where it now serves as product storage.

Drawing room

The drawing room was constructed at the time of the relocation of the brewery in 1949. The ceiling is designed to appear like the inside of an open umbrella and is called janome tenjo (janome refers to a traditional paper umbrella, more specifically, one with a bull’s eye design; tenjo means ceiling). The floor is made entirely of marble. The glass windows are originals from the time of construction, a vintage rarity. Back then, each piece of glass was created by hand, and the presence of air bubbles and slight distortions give the glass a quaint appeal. The seal carving mounted on the wall is the work of Randai Nakamura II.

Meiji Kura

This is the only wooden kura (brewhouse) that remains at Iinuma Honke today. The kura was given its name because it was constructed in the mid-Meiji period. Presently, the Meiji Kura is used as a venue to hold events.

Mae Kura

While the exact date of establishment is unknown, information gathered from preserved documents found within the storehouse suggests its likely construction to be in the late Edo period (1603 – 1867). The storehouse was used not only for sake brewing but also for storing daily household goods.

Kinoene omoya

Situated in a renovated, 300-year-old omoya (main wing) that has been a cherished residence for generations of the Iinuma family, Kinoene Omoya invites patrons to indulge in Japanese sake and culinary offerings inspired by the twenty-four solar terms of the Asian calendar. The space embraces its heritage with original beams and fittings still in place, and the tastefully furnished tables crafted from repurposed sake-making materials harmonize with chairs and lampshades produced by artisans. The renovation has created a serene ambiance and a new purpose as a place for social gatherings and shared moments. The twenty-four solar terms are deeply intertwined with the art of sake-making, and savoring the seasonal cuisine and sake in its place of origin makes the experience even more special.

Main gate

The main gate is constructed in a traditional style with a tiled roof called kabuki-mon. There are two gates at Iinuma Honke, one of which is located on the back end of the bottling facility and was formerly used as the main gate. However, when the Minami-Shisui Station opened and trolly tracks were laid, the current gate came to be used as the main gate.

Kinoene Magariya

Magariya (lit. bent house) refers to a style of architecture commonly seen in residences of the Tohoku region and is characterized by the L-shaped structure. Above the horse stable is a mezzanine called chishi where a small window is placed to let in light. Our magariya was formerly a private house in Kawagoe-mura, Higashi Kanbara-gun, Niigata Prefecture, a village that submerged under dam water. It was relocated to its present site and refurbished with a tiled roof. In October 1995, the building opened its doors to offer services to our customers. Initially, the business was limited to selling sake, but the lineup of products gradually expanded to foods and other specialty items. On the second floor is a gallery where featured exhibitions are held four to five times a year.

Visitor Center Sekitan-Goya

Guests are welcome to stop by our Visitor Center. Explore the brewery map and an exhibition area using repurposed vats utilized in the mashing process. Here, we highlight the craft of sake production, introduce our sake brewers, and trace the history of Iinuma Honke. On every fourth Sunday of the month, the center transforms into a lively Kinoene Asa-Ichi market, bustling with visitors and popular local vendors.

Kinoene SAKE CAMP

Stay the night in the brewery and awaken within its embrace. Our peaceful campsite nestled within the brewery grounds provides an opportunity for car-bound guests to fully engage in the Kinoene sake experience. Delight your senses with the seasonal offerings served at the restaurant, a renovated ancestral home where generations of the Iinuma family have resided. Indulge in an unparalleled and privileged experience of savoring sake under the starlit skies in the very location it was brewed. Gather by the fire with family and loved ones and share stories into the evening hours. Create your special camping experience only available within our sake brewery.

Lawn area

Surrounded by lush greenery, the expansive lawn area is open to various activities, and events are hosted throughout the year. Visitors can also enjoy camping on the weekends. It is a popular spot to spend a leisurely time whether as a family with small children, as a couple on a date, or alone to enjoy some me-time.

Parking lot

The paved parking lot is spacious enough to park large buses and fully equipped with restrooms.

Large refrigeration system

(freezer and refrigerator)

To ensure that our Kinoene Masamune reaches our customers in the most palatable condition, we have built a large, refrigerated storage unit where a portion of our products is stored. Within this refrigeration system is a large-capacity freezer unit to store unpasteurized sake and once-pasteurized sake products at -5 ℃ to maintain the freshness of unpasteurized sake for long periods.

Tours Movie