About us

Making of sake

Here is a step-by-step process into the making of our signature Kinoene Masamune with images of the facilities alongside explanations by Toji (Master Brewer) Kawaguchi.

1.Seimai (Polishing)

The outer surface of brown rice contains high levels of protein and fat, which degrades the flavor of sake. Therefore, the rice must be polished to reduce the amount of these components. The lower the rice polishing ratio, such as in daiginjo, the finished sake becomes richer in aroma and more refreshing and crisper in quality.

2. Senmai and Shinseki (Washing and steeping)

The purpose of washing the rice is to remove the bran remaining on the polished white rice. Washing shears off some of the surface of the white rice, so it is also called the second polish.

Once washed, white rice is soaked in water to allow it to absorb moisture to a certain extent. Steeping time may differ depending on the variety of rice, rice polishing ratio, whether it is for koji-mai (rice used to make koji) or kake-mai (rice that has been steamed and cooled), or the type of sake quality we are aiming to achieve. However, the goal is to let the rice absorb about 30% of its weight in water.

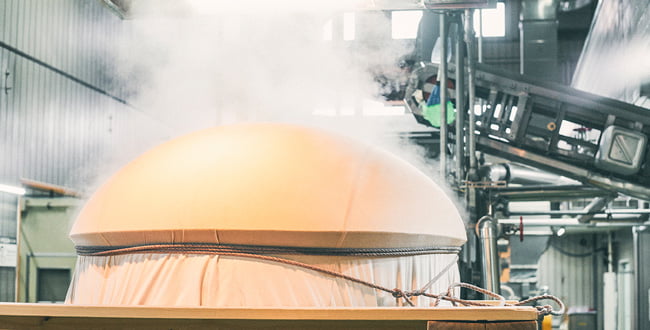

3.Mushi (Steaming)

The purpose of steaming the rice is to gelatinize the rice starch and convert it into an alpha form so that the rice becomes readily susceptible to the actions of koji enzymes. The heat also sterilizes the rice. A perfectly steamed rice should have a friable texture–hard on the outside and soft on the inside. The aim is to achieve a hard outer surface that does not stick to the hands when handled and an inside that is soft and fully steamed to the core.

4.Seikiku (Koji-making)

Koji is made by culturing koji mold (Aspergillus oryzae) on grains. Koji used for making seishu (a term synonymous with sake, meaning “clear sake” and referring to sake that has been strained) is prepared by adding spores of yellow koji mold to the rice and propagating the fungus over two days and nights while controlling the temperature and humidity. The primary role of koji is to produce saccharifying enzymes that break down the rice starch into glucose.

5.Shubo (Yeast starter)

A yeast starter is prepared as the pre-culture for moromi (sake mash). It is made by using a small tank to combine water for the mash, koji, and rice that has been steamed and cooled. Then, sake yeast is added to the mixture to propagate the yeast until its numbers increase, and the resulting product is the yeast starter. We cultivate a pure culture of high-quality sake yeast.

6.Moromi (Sake mash)

After cultivating batches of the powerful yeast, the yeast starter is moved to a larger tank. Here, more water for the mash, koji, and rice that has been steamed and cooled are added to the mixture in three stages to make the mash. This is called sandan shikomi, or the three-stage fermentation process. After the mash has been prepared, it is kept at a low temperature to allow a gradual maturation process until it develops the desired aroma while controlling the balance between saccharification and fermentation.

7.Joso/Assaku (Moromi pressing)

When the aroma of the moromi mash has fully matured, the mash is pressed and filtered to separate the seishu (strained, clear sake) from the sake-kasu (sake lees). In Japanese, this process is called joso (上槽 meaning “above the boat”) or assaku (圧搾 meaning “pressing”). The old method of filtering the moromi was done by pouring the mash into cloth bags called sake-bukuro and lining them inside a wooden boat-shaped vat to be pressed. The term, joso, originates from this method, but it continues to be used as the general name for the pressing/filtering process.

8.Bin-zume (Bottling)

After the sake has been pressed and filtered, it is bottled. At our brewery, we have implemented a method in which the sake is pasteurized in the bottle. We bottle and seal the sake in its “raw” or unpasteurized state and use a heated shower to sterilize it. The bottled sake is then placed in cold water to bring the temperature down. By reducing the length of time that sake is exposed to air, we can maintain the freshness and slightly fizzy mouthfeel similar to a directly bottled nama-zake (unpasteurized sake) even after the sake has been pasteurized.

9.Chozo (Storage)

The bottled sake is stored in a large-capacity refrigeration unit. We maintain the temperature at a constant level, which allows us to provide our customers with high-quality products throughout the year.

10.Shukka (Shipping)

When we receive an order, we will label and pack the bottles with great care and ship the sake to our customers.

Introduction to Sake

Introducing Iinuma Honke’s original visual handbook containing basic information about Japanese sake. Let us help you get acquainted with sake through easy-to-understand illustrations and informative text.